The next step after deciding your product specifications is to ensure that your products leaving your facility ALWAYS meet your specifications. Large food manufacturers have Quality Assurance (QA) and Quality Control (QC) Departments who carry out this role. They are often combined into one QA/QC division which carries out both functions of preventing defects and taking action when a defect occurs.

Quality Assurance prevents defects by organizing a system of checks, tests, and audits. These ensure that quality standards are defined and that basic food productions principles, as described in GMPs, are followed. Thus, QA includes the GMPS, SOPS, SSOPS, ingredient and product specifications, food safety and HACCP plans.

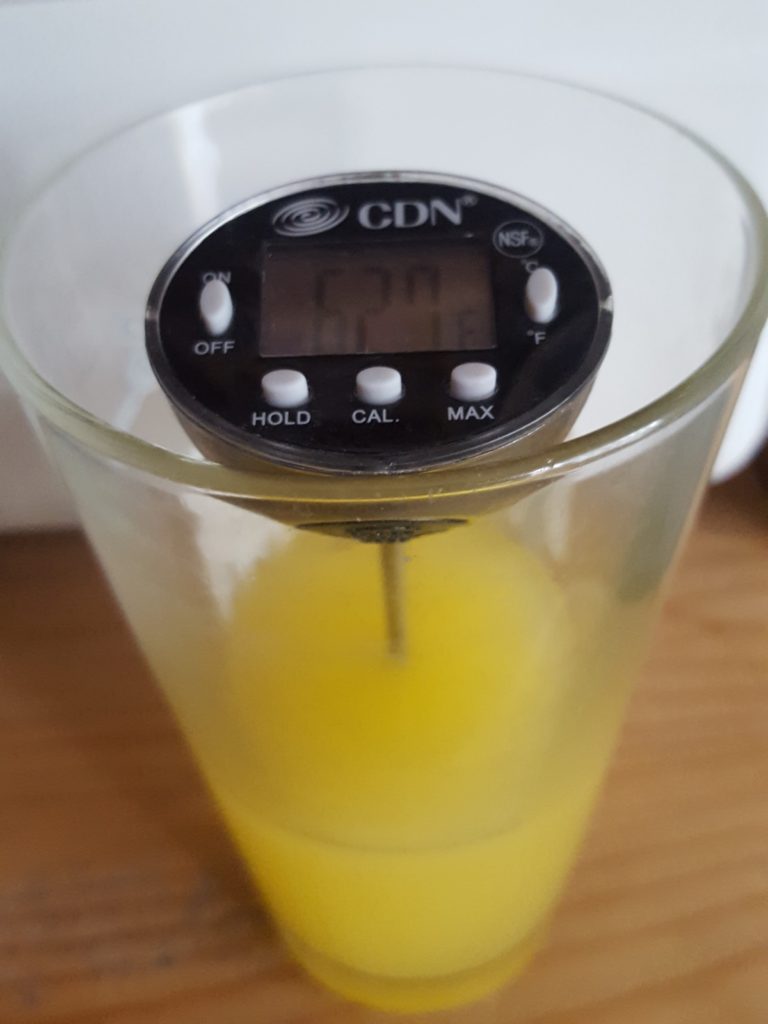

Quality Control is the monitoring procedures that verify and validate that the processes and procedures described by Quality Assurance are followed. Quality Control is the thermometer to check production temperature, the test strip to check sanitizer concentration, the microbial tests to check food is pathogen free. This monitoring and record keeping is also a legal requirement and can be used to update QA practices when failures are common.

Both QA and QC can be used to train employees to improve the safety and quality of the products they are responsible for making. The final decision for whether a product is sent to a customer should be made by the QA/QC manager. Legally, business owners and CEOs are responsible for the safety of the products leaving the facility. Most often they rely on their QA/QC department to do their jobs professionally and reliably.

Small food business, with few coworkers, may struggle to carry out QA-QC responsibilities as they seem like an additional chore. However, QA/QC can improve and tighten up the quality of your food products as, over time, you see where defects commonly occur. Additionally, this responsibility can be shared. Hiring a full time QA/QC manager can be expensive especially one who has the experience to have the experience, personal authority, and confidence to say “This product cannot be shipped”. A solution to this is a part-time consultant, who has the experience and authority but costs less than hiring a full-time co-worker. Interested? Book a call now!